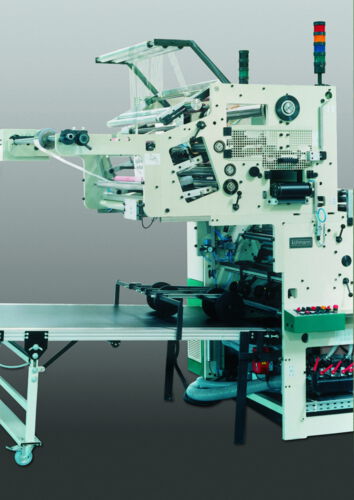

With this Unit you are able to produce so-called panorama boxes with a foil glued around the corner with a smooth bending edge and a punching out in a single working step.

Technical Description

Heating

Coming from the unwind unit the film will be delivered to the heating device.

The adjustable heating device heats the film in the creasing area to secure an optimal creasing quality of all kind of films. The heating device will be moved to the film stream by means of pneumatic cylinders while the machine is running. In case of machine stops the heating device will be moved back to avoid thermal damage of the film. The lateral setting of the heating devices can be set from outside of the machine by means of handles.

Creasing station

The heated film stream will be delivered to the creasing station afterwards. The creasing rollers can be set on and off during running of the machine from outside and run with the film over a hardened shaft. The hardened creasing rollers can be replaced; the corresponding creasing depth can be adjusted according to the foil thickness and use of the film. The lateral setting of the creasing devices can be set from outside of the machine by means of handles.

Punching unit

After the creasing station, the film will be delivered to the punching unit. Therefore the continuously running film will be stopped mechanically whilst a punching bar with the punching tools is carrying out the punch. During punching operation the foil movement is compensated by a swing which is mounted on the right and the left side of the punching bar. The punching unit is driven by a separate servo-motor.

As a standard this unit will effect 2 creases and 2 punches into the film stream. It may not be converted with same tooling depending on materials like PVC and PET. One more set of tools could be necessary due to the various materials to be converted.

Technical Specifications

| Distance between two scoring lines: | min. 60 mm |

| Foil length: | min. 100 mm - max. 650 mm |

| Foil thickness: | min. 100 mµ - max. 300 mµ |

| Foil width: | min. 120 mm (standard) |

| Min. distance between score and foil edge: | 12 mm (glue flap) |

| Width of punch: | min. 12 mm - max. 18 mm |

| Length of punch: (i.e. possible staggered or decentred punches) |

max. 200 mm |

| Overlapping of foil beyond window (glue area): | min. 12 mm (glue flap) |

| All a.m. data are standard. Other dimensions if possible on request. | |

| Reel inner diameter of foil rolls: | 76 or 150 mm |

| Speed: | up to max. 12.000 windows per hour depending on film type, thickness and cut off length |

| Lateral tolerances: | +/- 0,5 mm |

| Tolerances in running direction: | +/- 1,5 mm |

| Cut-off length of foil: | +/- 0,5 mm |